A WET-SPINNING LINE will be installed soon at CANOE Lacq

CANOE is very involved in the manufacturing of fibers, especially from bio-based materials such as cellulose or lignin. These fibers can be used as precursors for low cost carbon fibers, a continuous carbonization pilot line is already running at CANOE since August 2018, or be directly converted into textiles.

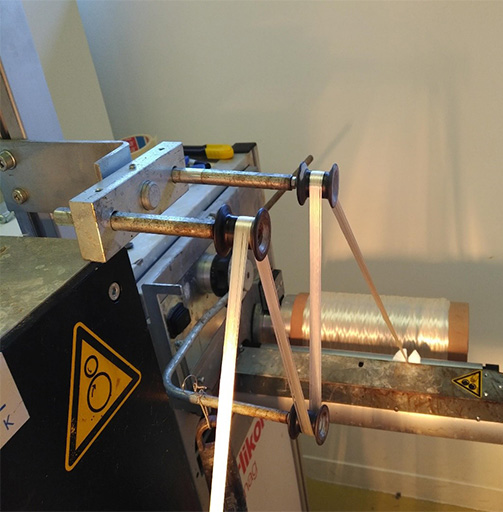

As part of the FORCE project, a wet-spinning pilot line will be installed during summer 2020 in CANOE facilities in Lacq, in particular to feed the carbonization line. This new wet-spinning line, unique in Europe, has a production capacity which is 6 times higher than the line in Pessac : it will allow the manufacture of yarns up to 3000 filaments by wet spinning and dry-jet-wet-spinning methods.

This line, ordered in September 2019, is co-funded by the Nouvelle Aquitaine regional board and IRT Jules Verne. The solvent spinning line is able to produce around 3 tons of fibers per year. It will be used for research contracts on the development of new functional fibers for CANOE’s customers and also for activities in collaborative projects. It allows the spinning of various types of polymers, such as cellulose, polyvinyl alcohol, lignin, polyacrylonitrile, alginate, …, after dissolution in a solvent like phosphoric acid, water, DMSO, ionic liquids, among others. The line is built with specific tools for the spinning dope preparation, a coagulation bath with on-line control of the solvent composition and different washing and stretching modules before the drying, the sizing and the winding units.

The FORCE project, led by IRT Jules Verne, aims to develop carbon fibers with a tensile strength of 2500 MPa and a Young’s modulus of 250 GPa, for a price of 8€/kg to supply to the automotive and sports and leisure markets. FORCE got now extended for two more years. The technical target is almost reached, therefore the main focus now lies on the spinning of low cost cellulose raw materials coming from recycled paper or end-of-life textiles.