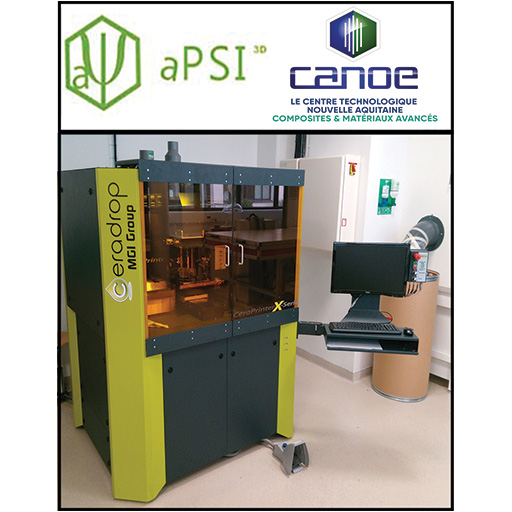

CANOE / aPSI3D: a successful collaboration thanks to inkjet 3D printing!

aPSI3D, a start-up company located in Tarbes (France), was developing SiC power module, designed for the hybrid and electrical vehicle market. At the final stage of development, they faced a great technological challenge at the packaging level of the electronic module. After discussing with the heads of CERADROP, inkjet 3D printing technology appeared to be a good choice to rapidly complete the module manufacturing. CANOE, a technological center in Nouvelle Aquitaine, was entrusted with this study, since they have a well-known expertise in formulating and processing polymer materials and good knowledge of the related processes. The CERADROP X-Series inkjet 3D printer, located in CANOE, led to numerous successful results in terms of design resolution and allowed to develop innovative material solutions (e.g. high temperature resistant, dielectrical ink compatible with substrates). After 6 months of study and a first series of tests, aPSI3D and CANOE are planning to go on with their collaboration in power packaging using inkjet 3D printing to face other challenges.